X Bar R Chart

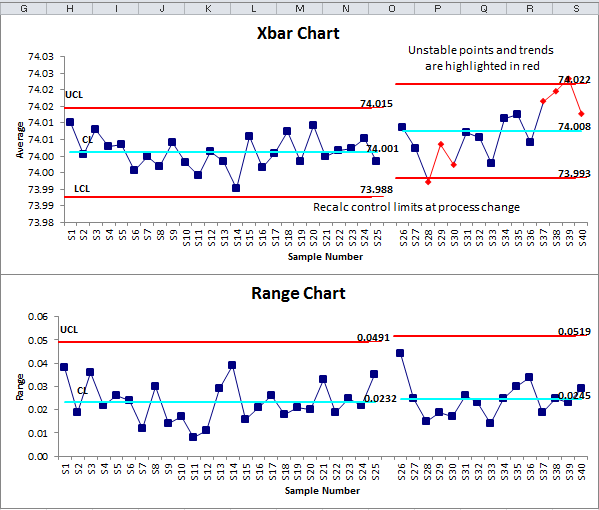

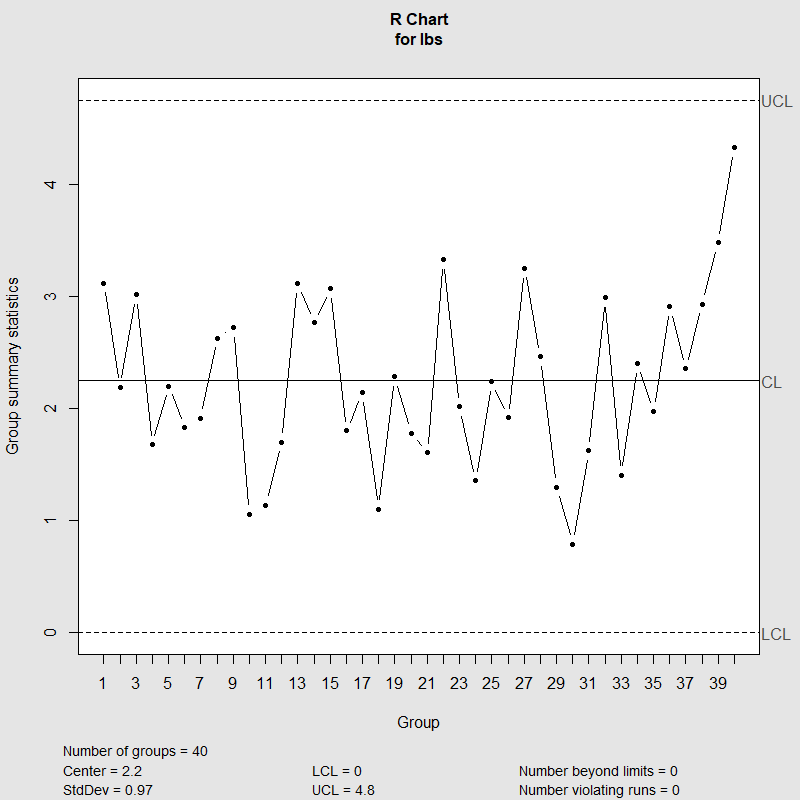

Engineers must take a special look at these points in order to identify and assign causes.

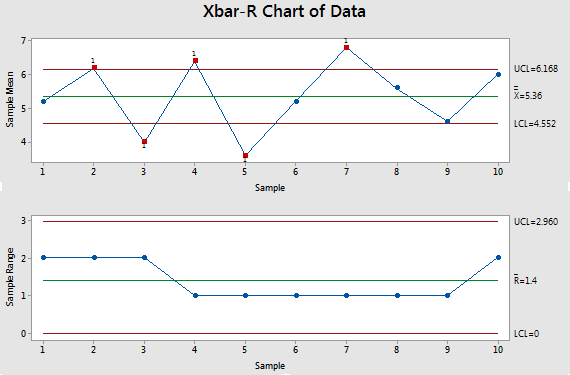

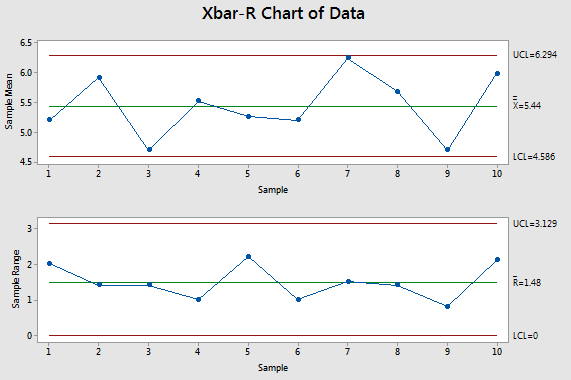

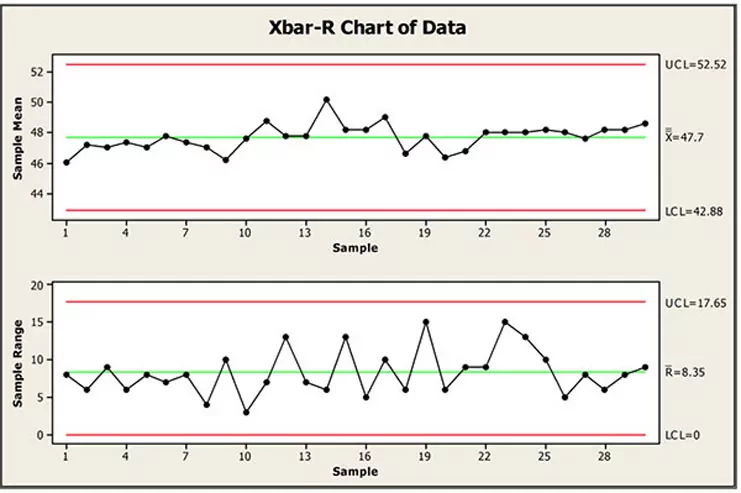

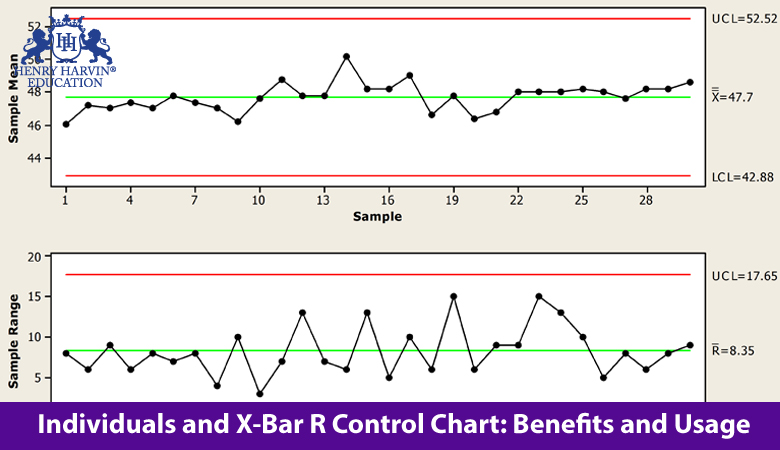

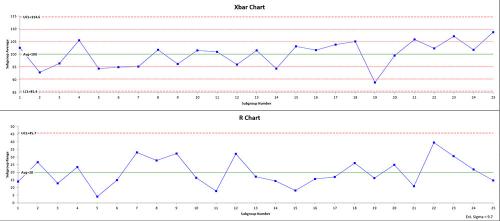

X bar r chart. The Mean X-Bar of each subgroup is charted on the top graph and the Range R of the. The X-bar chart is intended to have all data points outside the control limits because the control limits represent the measurement system variation. X bar R chart is used to monitor the process performance of a continuous data and the data to be collected in subgroups at a set time periods.

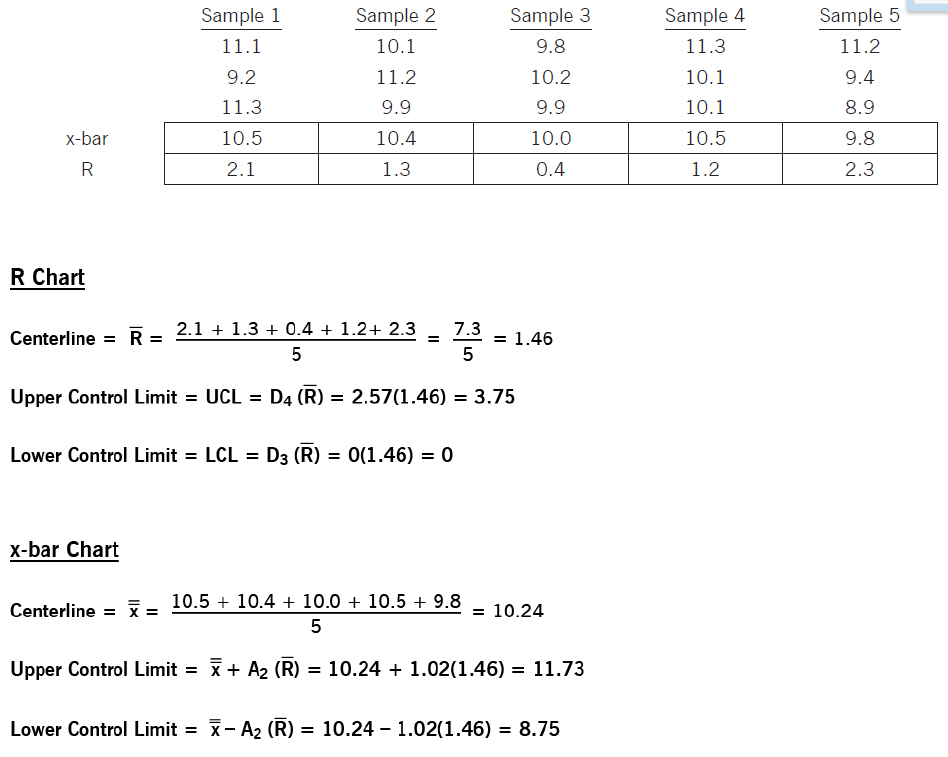

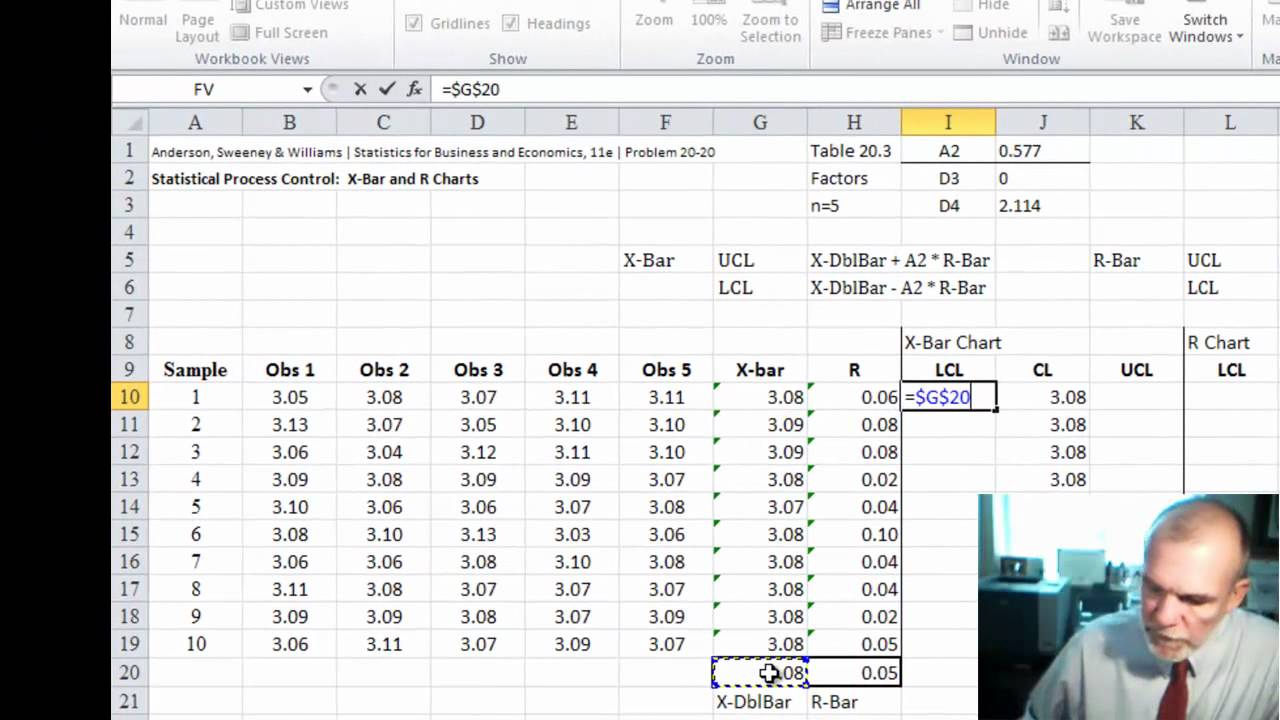

For example a manufacturing engineer. X-barR charts are a pair of control charts where continuous or variable data is collected in rational subgroups. K r R i.

K x x i Constructing x-bar charts Calculate the r-bar or overall mean of the ranges next This is needed to calculate the upper and lower control limits of the x-bar chart. X-bar and R Control Charts An X-Bar and R-Chart is a type of statistical process control chart for use with continuous data collected in subgroups at set time intervals - usually between 3 to 5 pieces per subgroup. Some notes to keep in mind when creating an x-bar R chart include.

Constructing x-bar charts Calculate the grand or overall mean by averaging all the sample means This becomes the center line of the x-bar chart. Interpreting an X-bar R Chart. An x-bar R chart can find the process mean x-bar and process range R over time.

Historically the X -bar and R charts have been the most commonly used control charts for the process mean and process variation in part because they are the simplest to calculate. X-bar and R Control Charts It is used to monitor the mean and variation of a process based on samples taken from the process at given times hours shifts days weeks months etc. The measurements of the samples at a given time constitute a subgroup.